Dataponics™/IoTA Controls™ Hardware Solutions

Dataponics™ offers the most comprehensive hardware and software solutions for controlled-environment agricultural automation. No other system matches our power, value, scalability, functionality or ease-of-use while giving you the power to access the system from anywhere in the world.

When you order a Dataponics system your hardware and software will be preconfigured and optimized by our team of expert designers and control logic engineers for your specific requirements. We guide you through the capabilities of the system and then configure it to operate in a way that will be most productive and intuitive for your operation.

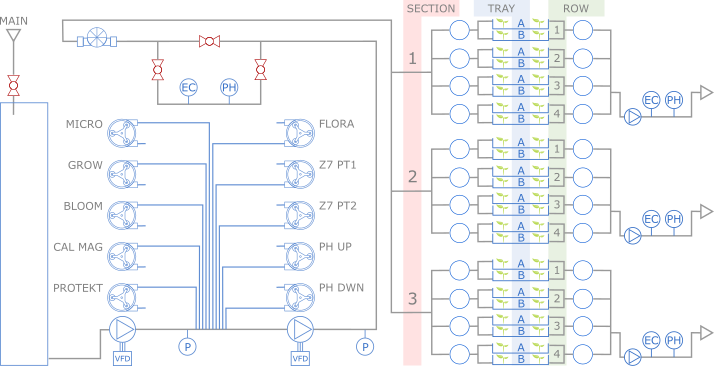

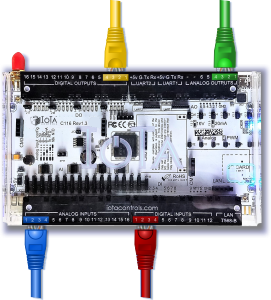

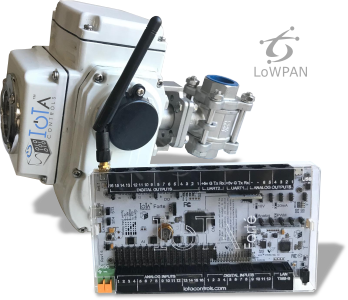

Forte™Controller

Controller/Cloud Gateway supports 50+ direct-wired IO’s and a virtually unlimited number of wireless devices. Co-developed with IoTA Controls™, they offer unmatched performance and value.

Learn more

Dataponics Environment™

Precision wireless sensors monitor critical zone parameters which can be used to automatically control HVAC, CO2 generators, dehumidifiers, lighting and other environmental equipment.

learn More

Dataponics Canopy™

Wirelessly scan the ambient canopy temperature and infrared radiation from leaves and flowers to monitor plant health and optimize watering and plant feeding cycles.

learn More

Dataponics pH/EC Suite™

Industrial-quality, high-precision analytical sensors, mounted on a single manifold, can be used to monitor inline influent injection of nutrients and additives or assess the the moisture and absorption of effluent runoff in real time.

learn More

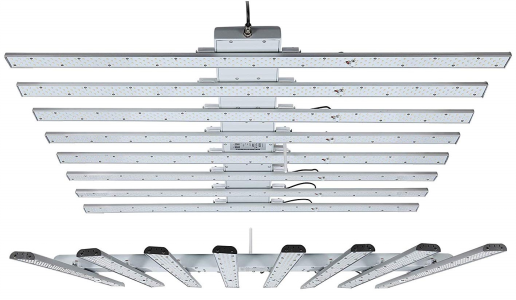

LED Light Intensity and Spectrum Control

Wirelessly control lighting schedules, intensity and RGB spectrum based on the latest science for optimized growth during all stages of plant development.

learn More

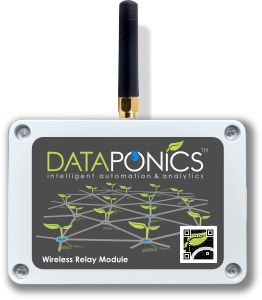

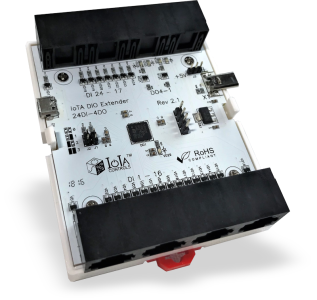

Dataponics RF Relay™

Powerful industrial-wireless modules provide for two SPDT relays capable of controlling HVAC, CO2 generators, dehumidifiers, lighting or just about anything else.

learn More